Environment and Energy Management

Working for a sustainable future, Tat Gıda works proactively, using digitalization to reduce its carbon emissions, energy consumption, and waste, to save water, and to measure its impact on nature.

Tat Gıda considers digital transformation in production to be an important tool for using global resources efficiently and making potential opportunities in this area visible, and it uses digital technologies to implement sustainable agricultural practices. In 2022, Tat Gıda completed many projects and designed applications in this regard.

In this regard, Tat developed a decision support system backed by artificial intelligence to reduce energy consumption in water supply. This made it easier to choose and use the most efficient water wells, ensuring that the smallest amount of electricity is consumed per unit of water. In another digitalization project, Tat Gıda aims to detect inefficiencies by observing how much electricity production lines consume and taking any actions necessary to reduce it. In addition, Tat Gıda engineers can use management dashboards to monitor energy consumption and intervene when inefficiencies are detected in a timely manner.

Tat Gıda works with an environmentally friendly approach by establishing regulations in production plants, investing in technological infrastructure, and maintaining high standards. Tat Gıda provides training to company employees and to farmers, so they learn about both resource utilization and efficient production techniques.

Tat Gıda has earned certificates for the ISO 50001 Energy Management System, ISO 14001 Environmental Management System, and ISO 14064 Greenhouse Gas Calculation and Verification Management System. In 2022, the company successfully completed the Unified Audit of the Ministry of Environment for ISO 14064 and Customer Audits.

In addition, Tat Gıda conducts environmental risk analyses on all its processes measuring noise, wastewater, water consumption, emissions, solid wastes, hazardous substances, odor, soil pollution, and the use of energy and natural resources. It has also installed an inline/online wastewater pollution measuring system called SAIS. The company uses these systems to measure compliance with legal limits.

| 2020(TL) | 2021(TL) | 2022(TL) | 2023(TL) | |

|---|---|---|---|---|

| Environmental Investments and Expenditures | 5.788.306 ₺ | 14.155.827 ₺ | 28.000.000 ₺ | 16.483.176 ₺ |

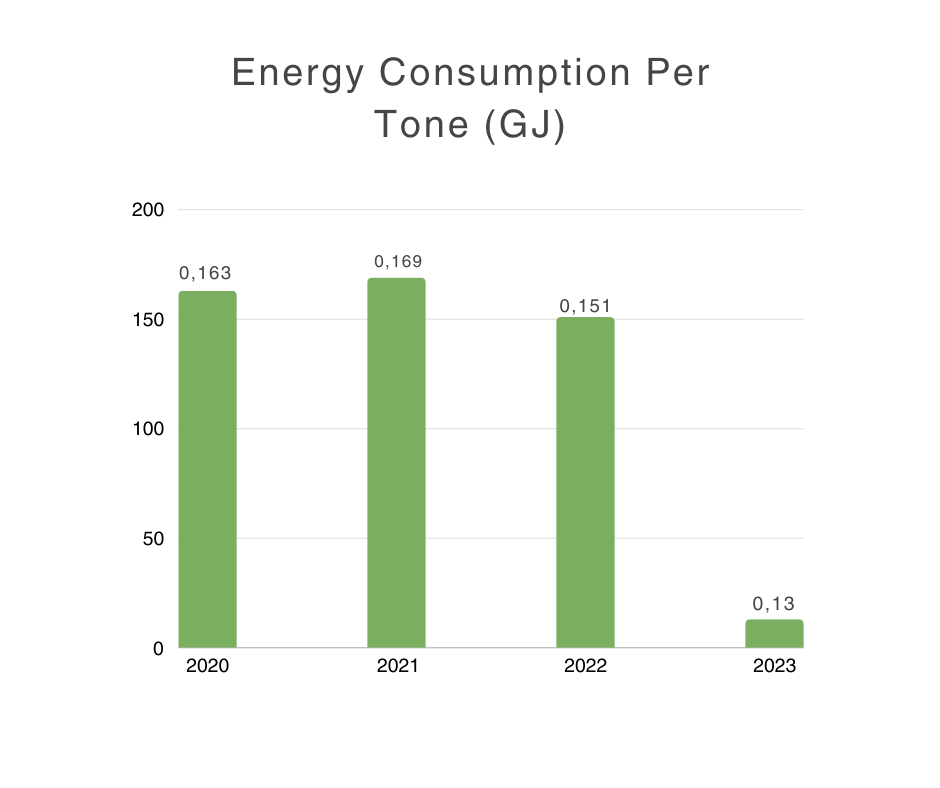

*These data shows the amount of indirectly and directly purchased energy from outside.

*The purchased electrical energy is 100% green energy.

Energy Consumption and Greenhouse Gas Emissions

Tat Gıda is well aware of the importance of sustainable agriculture and food practices, and many of its projects seek to specifically identify what measures can be taken to reduce the risks of climate change and to create action plans.

At Tat Gıda, we adopt a proactive approach to mitigating the impacts of climate change. In line with the Climate Action goal of the United Nations Sustainable Development Goals (SDGs) and the Paris Agreement, we are committed to reducing our carbon emissions and lowering our energy consumption.

As part of this commitment, we have joined the Zero Carbon Club, published by Fast Company, which includes companies that have pledged to achieve carbon neutrality. We aim to reduce our carbon emissions by 55% by 2030 and reach Net Zero by 2050. In alignment with our sustainability strategy, we actively promote climate-friendly practices across all our operations and prioritize projects that enhance energy efficiency.

Additionally, by signing the United Nations Global Compact (UNGC), we have pledged to uphold the 10 principles, which encompass human rights, labor standards, gender equality, environmental responsibility, and anti-corruption. In this regard, we are committed to minimizing our environmental footprint through energy efficiency measures and low-carbon production processes.

Tat Gıda aligns with national and international energy efficiency initiatives and operates within various regulatory frameworks. Specifically, we comply with Turkey’s National Energy Efficiency Strategy and Mandatory Emissions Reporting requirements.

The “Smart Water Resources Management System Supported by Artificial Intelligence” project aims to reduce electricity consumption by about 15%. Another project is the investment of 1.7 million USD to build an energy campus with a capacity of 2MW to supply all the electricity needs of the Torbalı, Izmir plant through solar energy. Other solar energy projects are in development to meet the electricity needs of other plants.

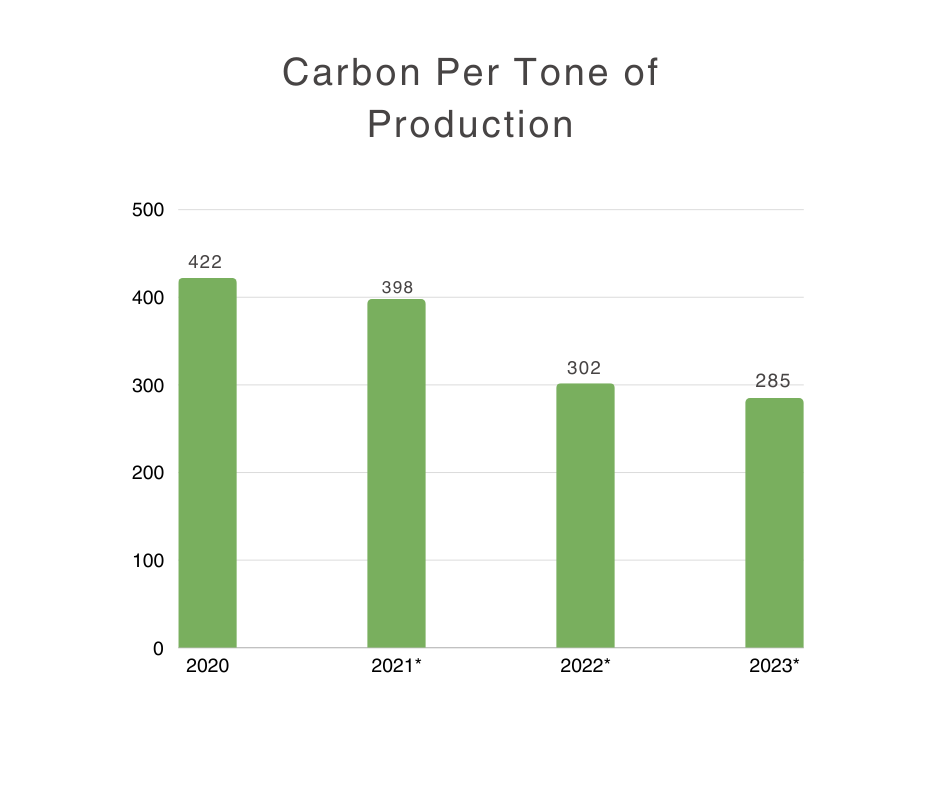

One of Tat Gıda’s main focuses in 2022 was realizing its vision of reducing carbon emissions while meeting the goal of leading in cost-efficiency and stakeholder commitment to ensure more environmentally friendly production. The calculations necessary for identifying our carbon footprint in 2022 were completed and long-term, science-based targets were set.

Revision of the ISO 14064 standard for the verification and approval of greenhouse gas declarations was completed in 2022.

Revision of the ISO 14064 standard for the verification and approval of greenhouse gas declarations was completed in 2022.

In this context, carbon emissions were divided into 3 groups with different scopes:

Scope 1: Covers emissions generated directly within the company. These include emissions from vehicles, natural gas consumption, use of refrigerant gases, etc.

Scope 2: Covers indirect consumption, including emissions from electricity consumption.

Scope 3: Covers other indirect consumption, including emissions from raw material use, packaging, waste disposal, etc. A 1,600,000 Euro investment in economizer systems in natural gas boilers, pre-evaporator waste steam recovery, efficient engine-pump applications, and production process modernization for efficient use of energy resources resulted in savings of 700,000 Euros.

Operational greenhouse gas emissions are tracked and measured and compared year by year.

| Green Gas Emissions | 2020 | 2021* | 2022* | 2023* |

|---|---|---|---|---|

| Scope 1 (ton Co2e ) | 36.953 | 43.260 | 45.555 | 38.662 |

| Scope 2 (ton Co2e ) | 7.667 | 10.735 | 0 | 0 |

| Total (ton Co2e ) | 44.620 | 53.995 | 45.555 | 38.662 |

| Carbon Emissions per Ton (kg CO2e) | 362 | 398 | 303 | 280 |

| Air Emissions | 2020 | 2021 | 2022 |

|---|---|---|---|

| NOx (Kg/hr) | 37.225 | 37.638 | 38.236 |

| SOx (Kg/hr) | 1.983 | 1.714 | 1.741 |

| PM (Particulate Matter) | 2.007 | 852 | 866 |

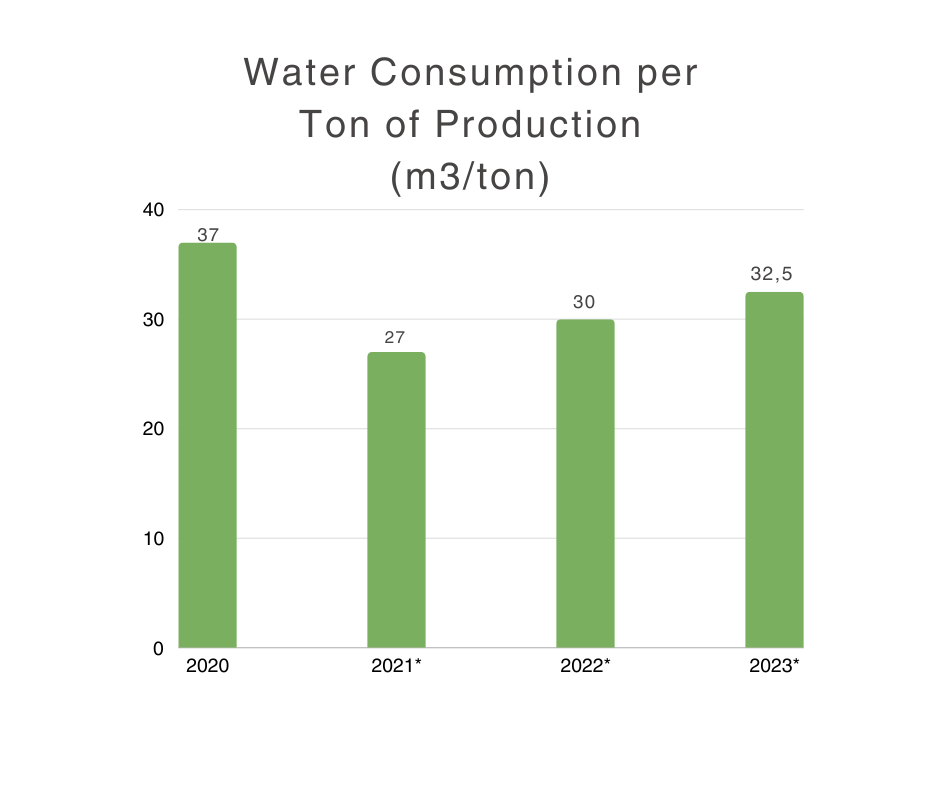

Managing Water Risks

Tat Gıda is careful about balancing its consumption of natural resources in agricultural production and takes preventive measures. Its priorities in this regard include ensuring environmental sustainability, using resources efficiently, and discharging wastewater in accordance with legal limits without harming the environment.

Wastewater treatment plants on our production lines follow an environmentally sensitive approach. The biological wastewater plant in the Mustafakemalpaşa factory is the largest privately owned facility of this sort in the region, and complies with Water Pollution Control Regulations, which dictate the legal limits for water discharge to bodies in the regions where our plants are located. The Ministry of Environment and affiliated Provincial Environmental Directorates monitor the treatment plant’s compliance with discharge standards 24/7 through the Continuous Wastewater Monitoring System Booths located in the plant. Moreover, treated wastewater from all wastewater treatment plants are regularly analyzed both in plants’ laboratories and by other accredited institutional laboratories.

Water saving projects implemented in plants increased their water recovery rate to 30%.

*Unverified

| Water and Waste Water Quantity | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|

| Water consumption (thousand m3) | 3.877 | 3.665 | 4.497 | 4.406 |

| Waste water quantity (thousand m3) | 37 | 27 | 30 | 32.5 |

| Water consumption per ton (thousand m3) | 3.551 | 3.295 | 4.047 | 3.969 |

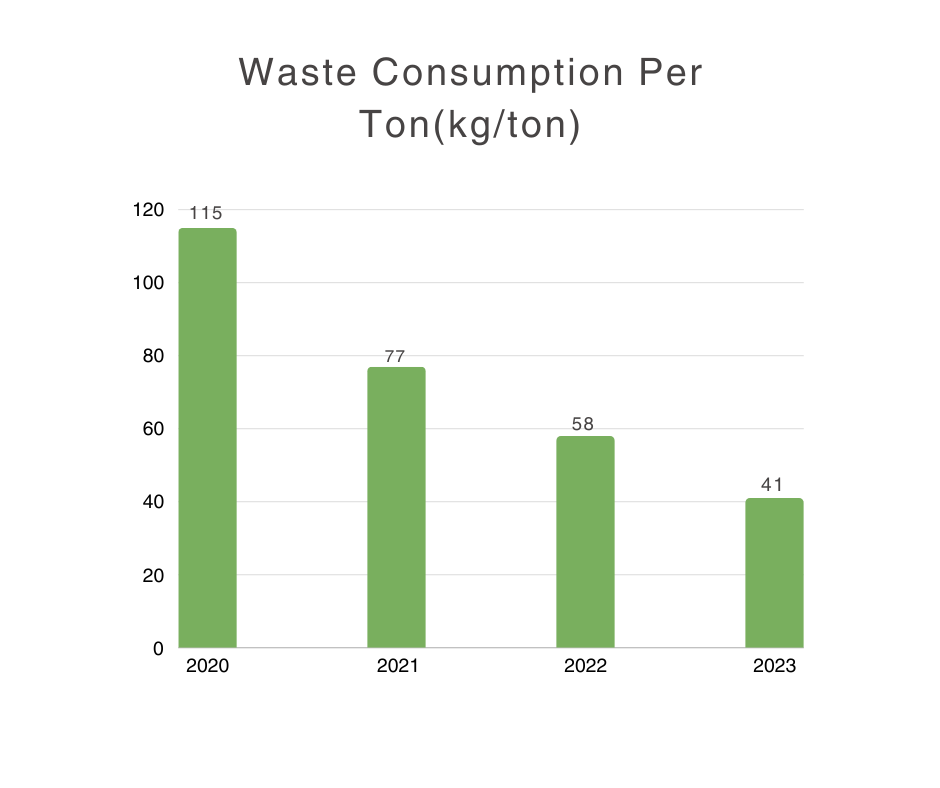

Waste Management

Tat Gıda considers waste management, energy consumption, and greenhouse gas emission reduction across its supply chain to be very important. It’s policy aims to reduce waste by preventing it at the source in its plants and facilities, and runs effective projects to reduce waste by recycling. In addition, Tat Gıda takes measures to reduce energy consumption and its greenhouse gases by cooperating with licensed companies to recover/generate energy from its production plants’ waste. Tat Gıda‘s use of recyclable packaging is another example of its approach to using resources more efficiently and its environmentally-sensitive production.

| Wastes (ton ) | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|

| Hazardous | 22 | 42 | 14 | 17 |

| Recycled | 3.998 | 3.355 | 2.213 | 2.440 |

| Send to landfill | * | * | 262 | 533 |

| Recovered for energy | 8.197 | 7.069 | 6.248 | 4.100 |

Zero Waste Management System

Tat Gıda contributes to the circular economy with its Zero Waste Management System, which monitors its environmental performance with the goal of continuous improvement.

Caring About Nature and Animal Habitats

Since the day it was founded, Tat has attached great importance to the greenery and landscape projects around its plants and works to create an aesthetic and ergonomic environment. With employee support, it created a 25-decare grove area around the Tat Gıda plant located in Mustafakemalpaşa, Bursa, featuring new pine, chestnut, cedar, silver spruce, fir, cypress, sycamore, ash, plum, loquat and palm trees, enlarging the grove that had already existed there.

Natural Habitats are considered important in Plant Areas to protect Anatolian squirrels of the genus Sciurus Anomalus, which live naturally in the area around the Mustafakemalpaşa plant, Tat Gıda has developed a biodiversity project, and built a ‘squirrel bridge’ and ‘squirrel houses’ in the trees around the plant.

At Tat Gıda, since the day we were founded, we have been continuously supporting all our stakeholders, protecting the land and nature where we produce, bringing healthy and delicious food to our consumers. We continue our activities in line with our responsible production approach, our environmental and sustainability efforts, and our sensitive approach that prioritizes the health and safety of all living things. To this end, in order to ensure animal welfare, we aim to switch to 100% cage-free egg supply in our production process by the end of 2025.